Exploring the Different Types of Warehouse Storage Systems

In today’s fast-paced business environment, efficient storage and organization are crucial for the success of any warehouse operation. Warehouse pallet storage racks play a vital role in optimizing space utilization and streamlining inventory management. In this blog post, we will delve into the world of warehouse storage systems, focusing on the various types of racks available and their benefits. Whether you are a warehouse manager looking to enhance productivity or a business owner seeking cost-effective storage solutions, understanding the different options will help you make informed decisions.

An Overview of Warehouse Pallet Storage Racks

Warehouse storage racks are specially designed structures that provide a systematic and organized approach to storing goods. These racks are designed to accommodate pallets, which are commonly used in the warehousing industry for efficient handling and transportation of goods. By utilizing warehouse racks, businesses can maximize their storage capacity, improve accessibility, and enhance overall operational efficiency.

Types of Warehouse Pallet Storage Racks

Selective Pallet Racking:

Selective pallet racking is the most common type of warehouse storage system. It allows for direct access to each pallet, making it ideal for businesses with a wide range of SKUs and frequent inventory turnover. This system is versatile, adjustable, and can be customized to fit specific warehouse requirements.

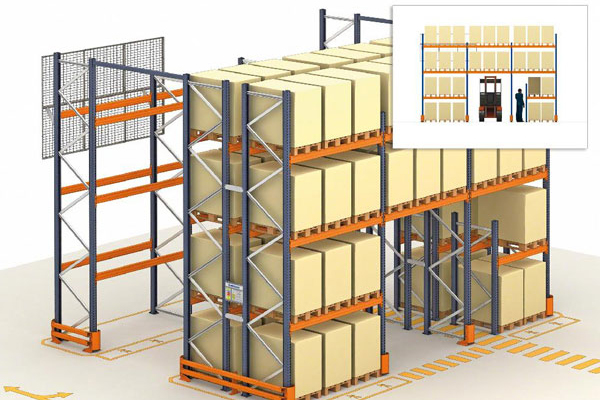

Drive-In Shelving:

Drive-in Shelving is a high-density storage system that maximizes space utilization by eliminating aisles between racks. It is suitable for storing large quantities of homogeneous products with low stock rotation. Forklifts can drive directly into the racks to deposit or retrieve pallets, making it a time-saving solution.

Push Back Racking:

Push back racking is a dynamic storage system that utilizes inclined rails and carts to store multiple pallets in a single lane. This system allows for high-density storage while maintaining selectivity and accessibility. It is particularly useful for businesses with a limited number of SKUs and a need for efficient stock rotation.

Cantilever Racking:

Cantilever racking is designed for the storage of long and bulky items such as lumber, pipes, and furniture. It features horizontal arms that extend from vertical columns, providing easy access and flexibility. This system is ideal for businesses in industries such as construction, manufacturing, and retail.

Benefits of Warehouse Pallet Storage Racks

Increased Storage Capacity:

Warehouse pallet storage racks enable businesses to utilize vertical space effectively, maximizing storage capacity without expanding the physical footprint. By stacking pallets vertically, warehouses can store more goods in the same area, optimizing their storage capabilities.

Improved Accessibility and Organization:

With warehouse pallet storage racks, inventory management becomes more efficient. Each pallet is easily accessible, allowing for quick retrieval and restocking. This enhances order fulfillment speed and reduces the time spent searching for specific items, leading to improved customer satisfaction.

Enhanced Safety:

Properly installed and maintained warehouse pallet storage racks contribute to a safer working environment. By keeping goods organized and secure, the risk of accidents and damage is minimized. Additionally, racks can be equipped with safety features such as beam locks and column protectors to further enhance workplace safety.