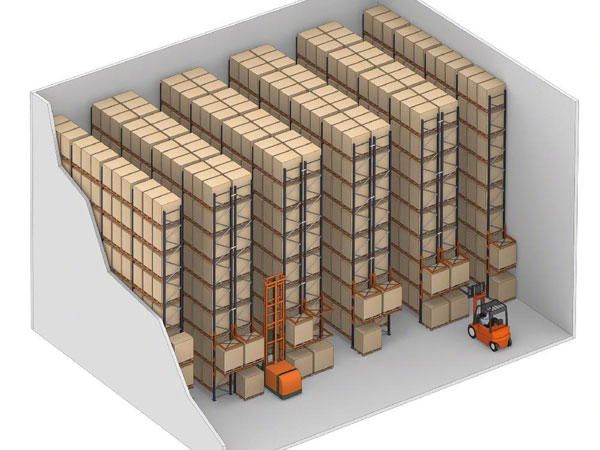

Warehouse Storage Solutions is essential part of warehouse infrastructure. To accelerate warehouse operations proper racking & shelving system should be in placed. With proper storage systems, warehouse operators optimizes space with efficient design and best suited racking system. The important aspect in racking system is to enable streamlined picking process. Warehouse layout plays a major role in warehouse racking, aisle width, docking locations, shipping areas, and other warehouse components affect warehouse racking options.

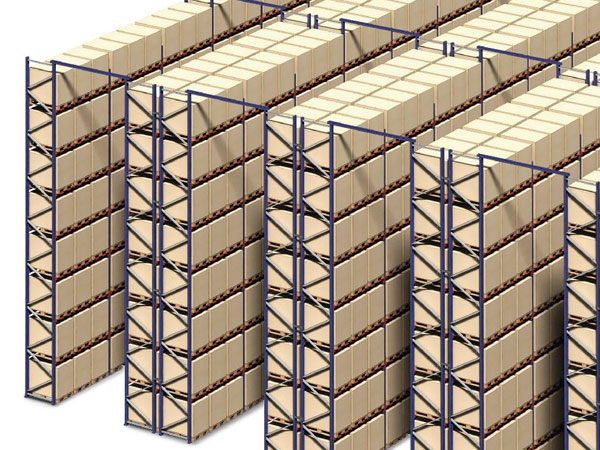

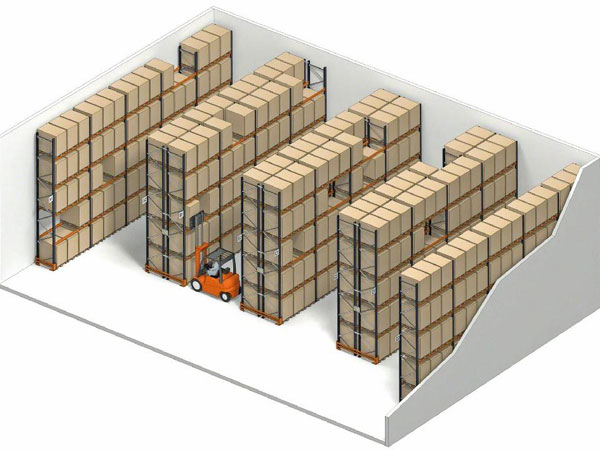

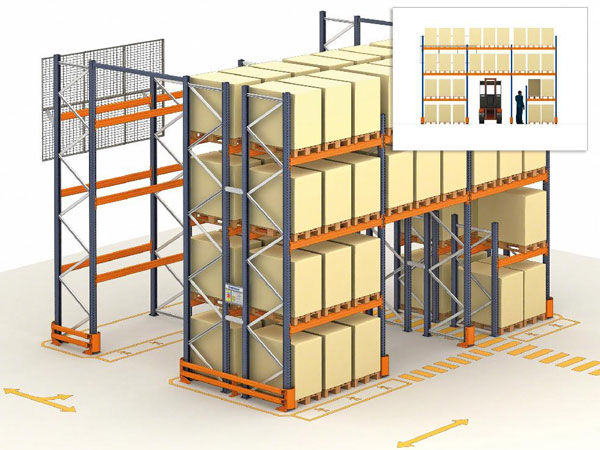

There are many types of Racking and Pallet Rack Systems or materials handling systems. Wooden, metal, or plastic pallets are combined with larger storage systems comprised of shelves at various levels. Decking bases are available in different widths to support small objects placed on the racks in storage. In many cases, industrial racks is several feet high and requires forklifts for the loading process. Various warehouse pallet rack & storage solutions configurations are possible including selective racks, drive-in or drive-through racks, push-back racks, and flow racks.

Requirements Of Warehouse Storage Solutions

There are a few factors to consider that help determine the best option for your company:

- Available floor space

- Ceiling height

- Cost

- Pallet type and size

- The number of SKUs stored in each rack

- Frequency of pallet access

- Product shelf life

- Number of pallets to be stored

- FIFO or LIFO product needs

Types of Warehouse Storage Systems

Warehouse Racking Systems

Warehouse Pallet Racking

Industrial Warehouse Racking

Pallet Warehouse Racking

Small Ware House Racks

Warehouse Racking and Pallet Rack

Innovative Warehouse Pallet Racks

Creative Warehouse Racks

Advantages of Warehouse Rack

- Modularity, Versatility, Convenience, and Customization

- Simple access

- Inventory management based on first-in, first-out (FIFO) principle

- Economical

- Allows several products to be accessed in the same column.

- There are no special truck requirements.

- Innovative & Creative Design

- Easily Manage Small Items